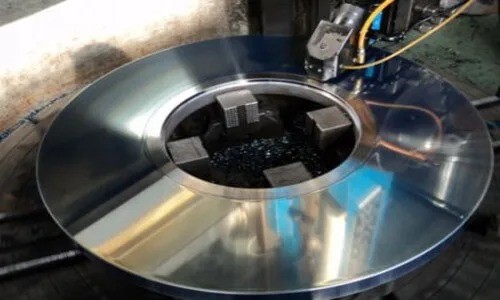

Enqubweni yokukhiqiza isikhunta, ingxenye eyenza isikhunta ngokuvamile idinga ukupholishwa ngaphezulu.Ukwenza kahle ubuchwepheshe bokupholisha kungathuthukisa ikhwalithi nempilo yesevisi yesikhunta futhi ngaleyo ndlela kuthuthukise ikhwalithi yomkhiqizo.Lesi sihloko sizokwethula isimiso sokusebenza kanye nenqubo yokupholisha isikhunta.

1. Indlela yokupholisha isikhunta kanye nesimiso sokusebenza

Ukupholisha isikhunta kuvame ukusebenzisa imicu yamatshe kawoyela, amasondo oboya, i-sandpaper, njll., ukuze ingaphezulu lempahla likhubazeke ngokwepulasitiki futhi ingxenye eyi-convex yobuso bomsebenzi wokusebenza isuswe ukuze kutholwe indawo ebushelelezi, ngokuvamile eyenziwa ngesandla. .Indlela yokugaya nokupholisha iyadingeka ngekhwalithi ephezulu.Ukugaya nokupholishwa okuhle kakhulu kwenziwa ngethuluzi lokugaya elikhethekile.Oketshezini lokupholisha oluqukethe ukuhuzuka, icindezelwa endaweni emshinini ukuze yenze ukunyakaza okujikelezayo kwesivinini esikhulu.Ukupholisha kungafinyelela ubulukhuni obuphezulu obungu-Ra0.008μm.

2. Inqubo yokupholisha

(1) upholishi olukhuni

Imishini emihle, i-EDM, ukugaya, njll. ingapholishwa nge-polish surface ejikelezayo enejubane lokujikeleza lika-35 000 kuya ku-40 000 r/min.Bese kuba khona ukugaya amatshe kawoyela okwenziwa ngesandla, umugqa wetshe likawoyela kanye nophalafini njengesithambiso noma isipholile.Uhlelo lokusetshenziswa ngu-180#→240#→320#→400#→600#→800#→1 000#.

(2) Ukupholisha kancane

Semi-finishing ikakhulukazi isebenzisa sandpaper kanye nophalafini.Inombolo ye-sandpaper iyalandelana:

400#→600#→800#→1000#→1200#→1500#.Eqinisweni, #1500 sandpaper isebenzisa kuphela insimbi yesikhunta elungele ukuqina (ngaphezulu kuka-52HRC), futhi ayifanele insimbi eqiniswe ngaphambili, ngoba ingase ibangele umonakalo ebusweni bensimbi eqiniswe ngaphambili futhi ayikwazi ukufeza umphumela wokupholisha oyifunayo.

(3) Ukupholisha kahle

Ukupholisha kahle ikakhulukazi kusebenzisa unamathisele we-diamond abrasive.Uma ukugaya ngesondo lendwangu yokupholisha ukuze kuxube idayimane impushana abrasive noma unamathisele abrasive, i-oda elivamile lokugaya ngu-9 μm (1 800 #) → 6 μm (3 000 #) → 3 μm (8 000 #).Ukunamathisela kwedayimane okungu-9 μm kanye nesondo lendwangu yokupholisha kungasetshenziswa ukususa izimpawu zezinwele ku-sandpaper engu-1 200# kanye no-1 50 0#.Ukupholisha bese kwenziwa ngokunamathisela okuzwayo kanye nedayimane ngokulandelana kuka-1 μm (14 000 #) → 1/2 μm (60 000 #) → 1/4 μm (100 000 #).

(4) Indawo yokusebenza ephucuziwe

Inqubo yokupholisha kufanele yenziwe ngokuhlukana ezindaweni ezimbili zokusebenza, okungukuthi, indawo yokucubungula ukugaya kanye nendawo yokucubungula kahle yokucwenga ihlukaniswe, futhi kufanele kuthathwe ukunakekelwa ukuze kuhlanzwe izinhlayiya zesihlabathi ezisele ebusweni be-workpiece esikhathini esidlule. inqubo.

Ngokuvamile, ngemva kokupholishwa okungalungile ngetshe likawoyela ukuya ku-1200# sandpaper, isiqeshana somsebenzi sidinga ukupholishwa ukuze sihlanzeke ngaphandle kothuli, kuqinisekiswe ukuthi azikho izinhlayiya zothuli emoyeni ezinamathela endaweni yesikhunta.Izidingo zokunemba ezingaphezu kuka-1 μm (kuhlanganise no-1 μm) zingenziwa ekamelweni lokupholisha elihlanzekile.Ukupholisha okunembe kakhudlwana, kufanele kube sendaweni ehlanzeke ngokuphelele, njengoba uthuli, intuthu, inkwethu namaconsi amanzi kungalaxaza izindawo ezipholishelwe ezinembayo.

Ngemuva kokuthi inqubo yokupholisha isiqediwe, ingaphezulu le-workpiece kufanele livikelwe othulini.Lapho inqubo yokupholisha imisiwe, wonke ama-abrasives kanye nezinto zokugcoba kufanele zisuswe ngokucophelela ukuze kuqinisekiswe ukuthi ubuso be-workpiece buhlanzekile, bese ungqimba lwe-mold anti-rust coating kufanele lufafazwe ebusweni bomsebenzi.

Isikhathi sokuthumela: Jan-10-2021